- Climatic Chambers

- Products

- Temperature Humidity Test Chambers

- Battery Test Chambers

- Rapid Temperature Change Test Chambers

- Thermal Shock Chambers

- UV Accelerated Aging Test Chambers

- Xenon Test Chambers

- Altitude Test Chambers

- Precision High Temperature Ovens

- Accelerated Aging Test Chambers

- Sand Dust test chambers

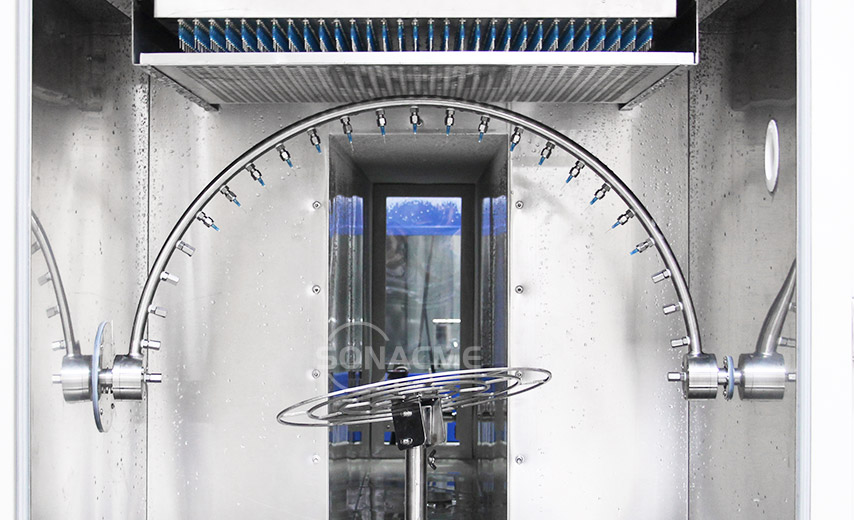

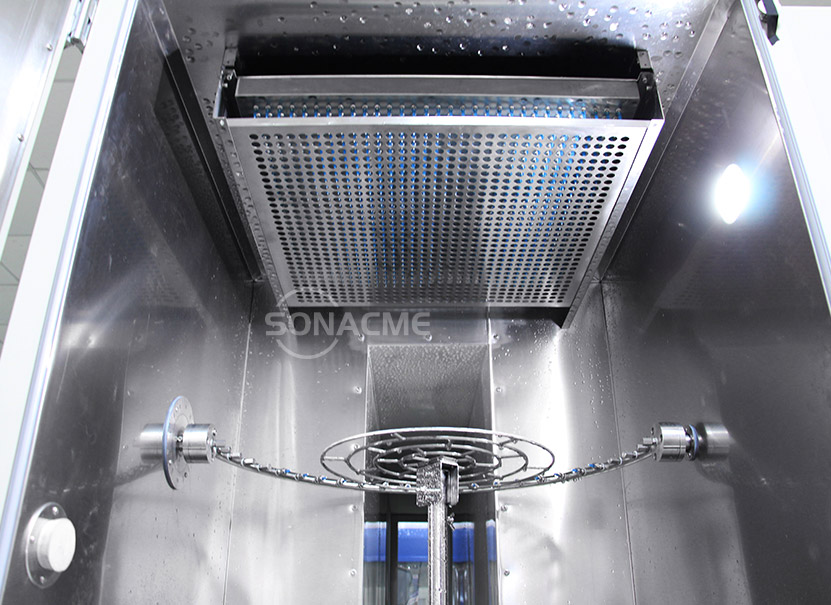

- Rain Test Chambers

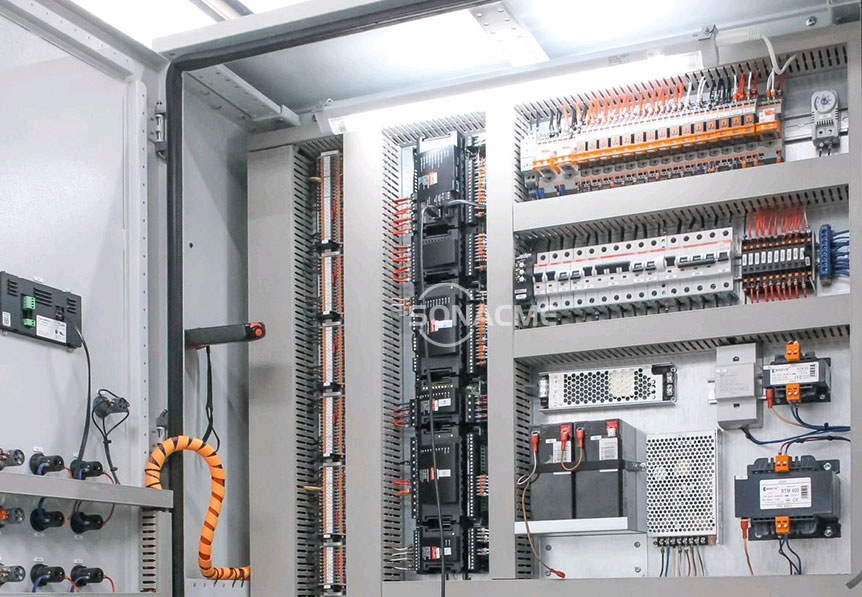

- Climatic Chambers

- Altitude Training Systems

- Industries

- About

- News

- Contact

+86-180 2704 9206

+86-180 2704 9206 WhatsApp:+86-180 2704 9206

WhatsApp:+86-180 2704 9206 info@sonacme.com

info@sonacme.com