What should I do if the Humidity Chamber fails?

Publish Time:2021-10-14Views:()

When it comes to the topic of repair and maintenance of test equipment when it fails, I believe that many quality laboratory personnel and purchasing personnel have bothered abo...

When it comes to the topic of repair and maintenance of test equipment when it fails, I believe that many quality laboratory personnel and purchasing personnel have bothered about it. Since these instruments and equipment are used, problems such as machine failures are certainly inevitable. Below, the editor of Huanyi sorts out the common troubleshooting of Humidity Chamber. The editor feels it is necessary to understand how to deal with the failure of Humidity Chamber. (If the repair and maintenance of professional problems are still done by our manufacturer, the effect is fast and efficient)

One. Common troubleshooting of Humidity Chamber:

1. Compressor overpressure alarm (too much refrigerant, high ambient temperature, dirty condenser, damaged condensing fan)

2. Compressor overcurrent protection (increase the thermal overload relay current, or replace the thermal overload relay one size larger)

3. Circulating fan overcurrent (regulate the current of the thermal overload relay, or replace the thermal overload relay one size larger)

4. The water tank is short of water (add pure water to the water tank to about two-thirds of the water tank)

5. Insufficient water pressure (check whether the cooling water tower is working properly and whether the cooling water pipe filter is dirty or blocked) 6. The laboratory temperature is too high (regulate the over-temperature protection, generally 20 degrees Celsius higher than the maximum temperature of the equipment. Control the temperature solid state relay load end breakdown, replace the solid state relay; the circulating fan is stuck or damaged)

7. The humidification tube is burnt empty (check whether the screw of the humidification tube protects the float ball is loose, and readjust it to a suitable height. Increase the humidification tube over temperature to protect it at about 180 degrees Celsius)

8. Phase sequence protection (change the position of the two live wires arbitrarily after power failure; check whether the voltage of each phase is normal with a multimeter)

9. The cooling effect of the equipment is not good (the laboratory load is too large; the refrigeration system is leaking refrigerant; the drying filter is dirty or the capillary is blocked, the condenser fin is too dirty, use an air gun to blow the dust on the condenser fin; Ice, defrost at high temperature)

One. Common troubleshooting of Humidity Chamber:

1. Compressor overpressure alarm (too much refrigerant, high ambient temperature, dirty condenser, damaged condensing fan)

2. Compressor overcurrent protection (increase the thermal overload relay current, or replace the thermal overload relay one size larger)

3. Circulating fan overcurrent (regulate the current of the thermal overload relay, or replace the thermal overload relay one size larger)

4. The water tank is short of water (add pure water to the water tank to about two-thirds of the water tank)

5. Insufficient water pressure (check whether the cooling water tower is working properly and whether the cooling water pipe filter is dirty or blocked) 6. The laboratory temperature is too high (regulate the over-temperature protection, generally 20 degrees Celsius higher than the maximum temperature of the equipment. Control the temperature solid state relay load end breakdown, replace the solid state relay; the circulating fan is stuck or damaged)

7. The humidification tube is burnt empty (check whether the screw of the humidification tube protects the float ball is loose, and readjust it to a suitable height. Increase the humidification tube over temperature to protect it at about 180 degrees Celsius)

8. Phase sequence protection (change the position of the two live wires arbitrarily after power failure; check whether the voltage of each phase is normal with a multimeter)

9. The cooling effect of the equipment is not good (the laboratory load is too large; the refrigeration system is leaking refrigerant; the drying filter is dirty or the capillary is blocked, the condenser fin is too dirty, use an air gun to blow the dust on the condenser fin; Ice, defrost at high temperature)

Latest News

-

SONACME Technology's delive...

When it comes to the topic of repair and maintenance...

-

SONACME Technology wishes y...

When it comes to the topic of repair and maintenance...

-

Application Guide of SONACM...

When it comes to the topic of repair and maintenance...

-

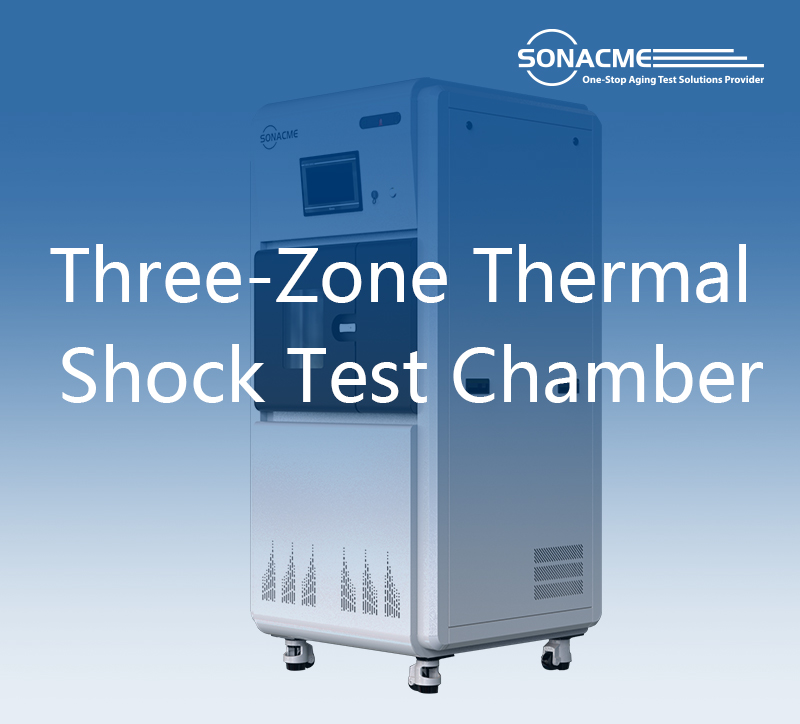

Three-Zone Thermal Shock Te...

When it comes to the topic of repair and maintenance...

-

AGREE Test Chamber: A tripl...

When it comes to the topic of repair and maintenance...

-

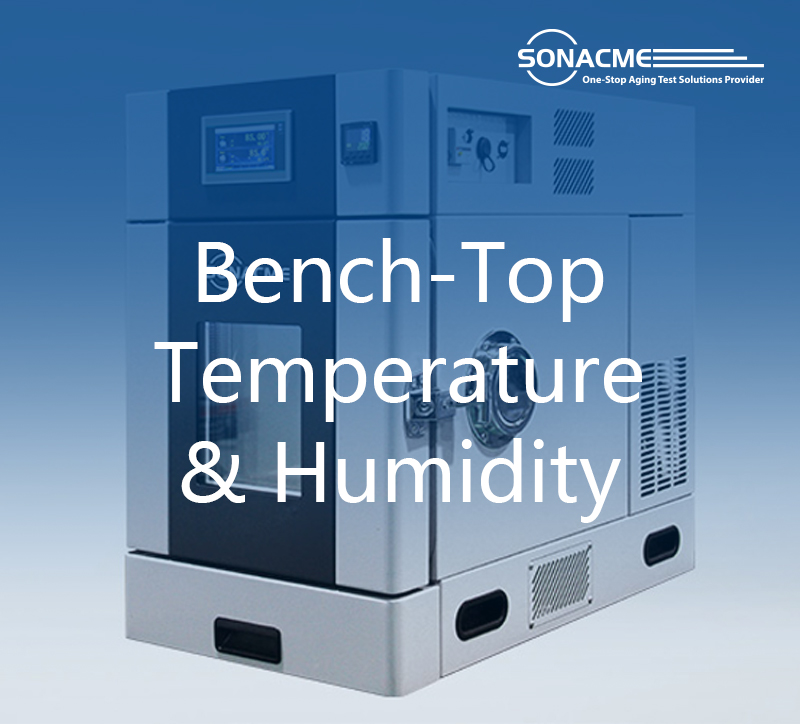

Bench-Top Temperature & Hum...

When it comes to the topic of repair and maintenance...

+86-180 2704 9206

Tel:+86(0769)83234966

E-Mail:info@sonacme.com

Contacts:Marcia/+86-180 2704 9206

Add:Building 7, No.310 Songbai Road, Liaobu Town, Dongguan City, Guangdong

+86-180 2704 9206

+86-180 2704 9206 WhatsApp:+86-180 2704 9206

WhatsApp:+86-180 2704 9206 info@sonacme.com

info@sonacme.com